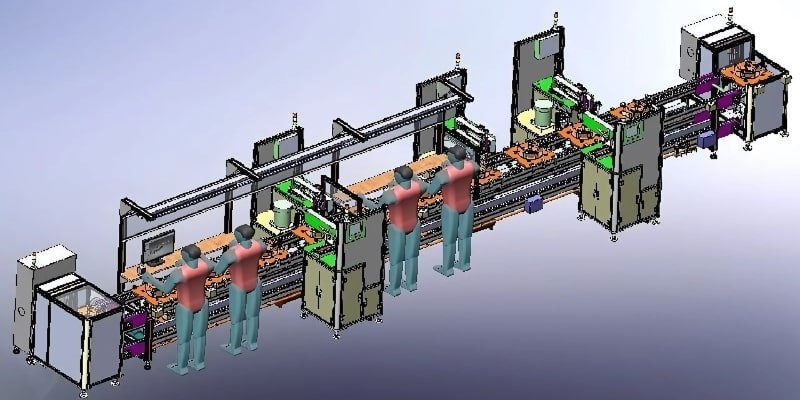

Assembly Line Automation refers to the use of automated systems, such as robots, conveyors, and computer-controlled machinery, to perform repetitive and labor-intensive tasks in a manufacturing assembly line. This technology is designed to increase production efficiency, improve product quality, and reduce costs by minimizing human intervention.

Core Elements of Assembly Line Automation

Assembly line automation relies on advanced technologies to optimize manufacturing processes. Robotic systems efficiently handle tasks such as welding, painting, assembling, and performing quality checks, ensuring speed and precision. Conveyors seamlessly transport components between workstations, maintaining a steady workflow. Sensors and vision systems enhance accuracy by detecting and correcting errors in real-time, reducing defects.