Hot Plate Welding is a thermal welding process used to join thermoplastic materials by applying heat and pressure. This method is especially useful for joining large or thick parts and ensures strong, durable bonds in applications where high precision is required. Hot plate welding is widely used in industries like automotive, aerospace, and packaging, as well as for producing consumer goods.

Advantages of Hot Plate Welding

Hot Plate Welding is known for creating strong welds, forming permanent, high-strength bonds that are ideal for demanding applications. Its versatility allows it to be used with a wide range of thermoplastic materials, making it suitable for various industries. The process is particularly effective for welding large parts, including complex and intricate shapes that other welding methods may struggle with. Additionally, Hot Plate Welding can be easily automated, making it highly efficient for high-volume production environments, where consistent quality and speed are critical.

Applications Across Industries

In the automotive industry, it is used to weld plastic parts for car interiors, fuel tanks, and other critical components, ensuring durable and secure joints. In packaging, it plays a key role in sealing large plastic containers and packaging materials, providing efficient and reliable sealing solutions. The medical device sector also benefits from hot plate welding, particularly in the creation of contamination-free, precise welds for components such as drug delivery systems. Additionally, in the consumer goods industry, hot plate welding is employed to join plastic casings for electronics, appliances, and toys, ensuring both functionality and aesthetic appeal in finished products.

Limitations Of Hot Plate Wilding

Hot plate welding is limited by material compatibility, as it only works with thermoplastics and cannot be used for metals or thermosetting plastics. Additionally, surface preparation is crucial for ensuring a strong weld, as the parts must be clean and free from contaminants before welding. The process can also have longer cycle times compared to other welding methods, particularly when working with thicker materials, which may impact production efficiency in high-volume operations.

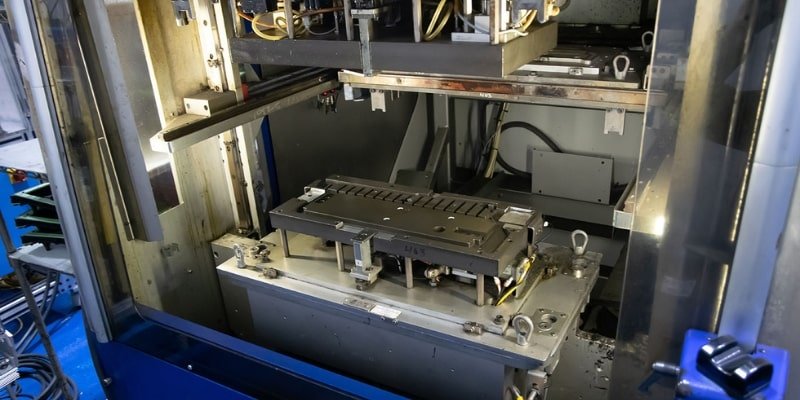

PAC World Technology’s Role in Hot Plate Welding

PAC World Technology can design and integrate automated hot plate welding solutions to improve production efficiency, ensuring high-quality welds for various thermoplastic components. Their expertise includes custom fixture design and ensuring that the welding process meets the exact requirements of their clients.