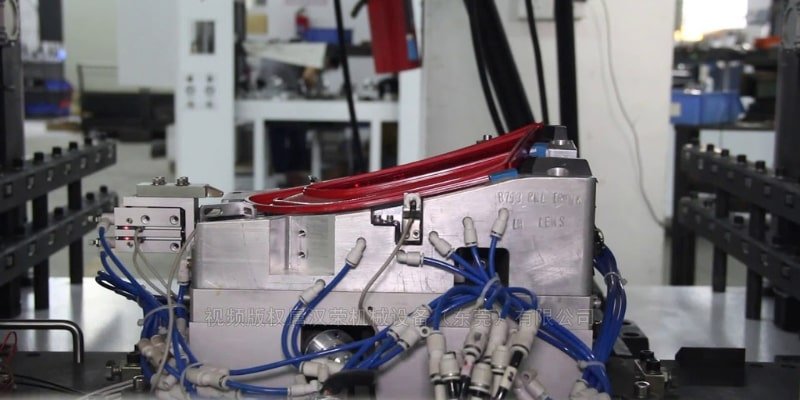

A Servo Hot Plate Welding Machine is a specialized piece of equipment used in the manufacturing industry for joining thermoplastic materials through the application of heat and pressure. This type of welding machine utilizes a servo-controlled hot plate to heat the parts to be welded, allowing them to fuse together. Servo Hot Plate Welding is particularly effective for producing high-quality, strong, and reliable welds in a range of industrial applications.

Advantages of Servo Hot Plate Welding

The servo-controlled system allows for precise adjustments in speed, pressure, and temperature, ensuring high-quality welds with minimal variability.The servo-controlled hot plates deliver consistent and even heat across the welding surface, which helps achieve strong and uniform welds.Servo Hot Plate Welding is suitable for a wide range of materials, including thermoplastics, composites, and some metals. It is also versatile in terms of the shape and size of components that can be welded.The process produces strong, durable welds that can withstand high stress and pressure, making it ideal for industries that require robust, long-lasting joints, such as automotive, aerospace, and electronics.

Applications of Servo Hot Plate Welding

Welding plastic parts, such as dashboards, bumpers, and interior components, which require high strength and a precise weld.Joining plastic components in the production of electronic devices, where the strength of the weld and the appearance of the parts are critical.Welding plastic parts used in medical devices, ensuring that the welded joints meet the high standards of quality and durability required in medical applications.Joining plastic or thermoplastic components in the production of household goods, toys, and other consumer products.

PAC World Technology’s Role In Servo Hot Plate Welding Machines

PAC World Technology can offer Servo Hot Plate Welding solutions designed to meet the specific requirements of various industries. The company can customize these systems to integrate with existing manufacturing processes and improve efficiency, accuracy, and product quality. They can also provide ongoing support to ensure that the machines remain operational and efficient over time.