Fabrication

Precision Fabrication: Built to Perform

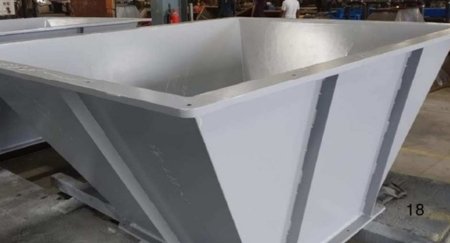

Our mission is to deliver exceptional quality in the fabrication, installation, and erection of structural and process equipment. Our state-of-the-art fabrication facility is equipped with advanced tools, including a dedicated fabrication shop, plasma cutting and oxy-fuel cutting systems, welding and drilling machines, rolling equipment, and painting units. With this infrastructure and a team of experienced personnel, we are well-equipped to handle specialized orders for both conventional structural projects and complex heavy-duty work, ensuring precision and excellence in every task we undertake.

Our Facilities

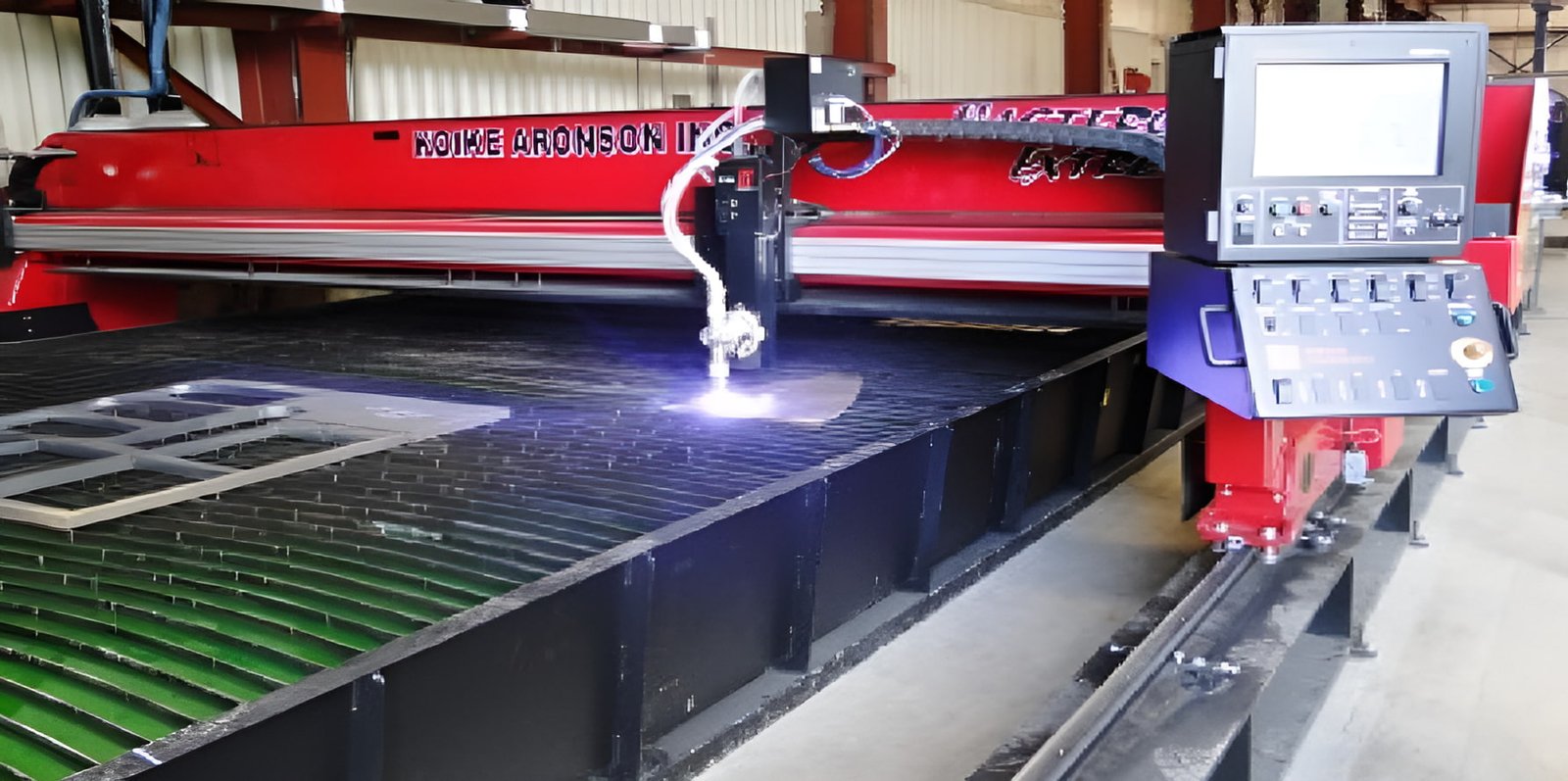

Cutting Facilities- Plasma Cutting&Oxy-Fuel Cutting Machine

| Description | Specifications |

|---|---|

| Actual Bed Size | 4 m x 8 m |

| Effective Cutting Bed Size | 2.8 m x 9 m |

| Cutting Speed | 2 m / min |

| Cutting Accuracy | 0.3 to 0.5 mm / m |

| Cutting Thickness Range | 10mm to 100 mm |

| Numbering System | Powder type |

| Quantity | 1 no. |

| Description | Specifications |

|---|---|

| Model | Hi~Arc – M400R |

| Current | 400-500 Amp 60% Duty cycle |

| Technology | Inverter base, IGBT Based |

| Weight | 15Kg |

| Fuse Supply | 25 amp |

| Quantity | 5 nos. |

| Description | Specifications |

|---|---|

| Model | SPL2820 |

| Cutting Thickness | 1/8 ~ ¼ In. |

Various Types Of Piping Works

As industrial piping contractors, we offer turnkey

solutions from concept, design, engineering to

supply, fabrication, installation, commissioning for complete plant utility piping system such as Fire

Fighting, G.I. & S.S. Piping for compressed air,

water, steam, thermic fluid, oil, gas, vacuum etc.